CALL US NOW!

FLOWER MOUND AND DFW

Elastomeric Roof Coating

CONTRACTORS

- Industry-leading materials

- Complimentary roof inspections

- Commercial maintenance program offered

Elastomeric roof coating offers a flexible, durable way to protect and extend the lifespan of your roof. This guide covers everything you need to know about its benefits and uses.

BOOK YOUR FREE INSPECTION

We will get back to you as soon as possible.

Please try again later.

Key Takeaways

- Elastomeric roof coatings are flexible, fluid-applied membranes that form a seamless, waterproof barrier, significantly extending roof lifespan and offering a cost-effective alternative to full replacements.

- Key types of elastomeric coatings include acrylic, silicone, and polyurethane, each providing unique benefits such as energy cost reduction, water resistance, and high impact durability.

- Regular maintenance and proper application of elastomeric coatings can add 10 to 25 years to a roof’s lifespan, while also contributing to energy efficiency and environmental sustainability.

Commercial

ButtonWhat is Elastomeric Roof Coating?

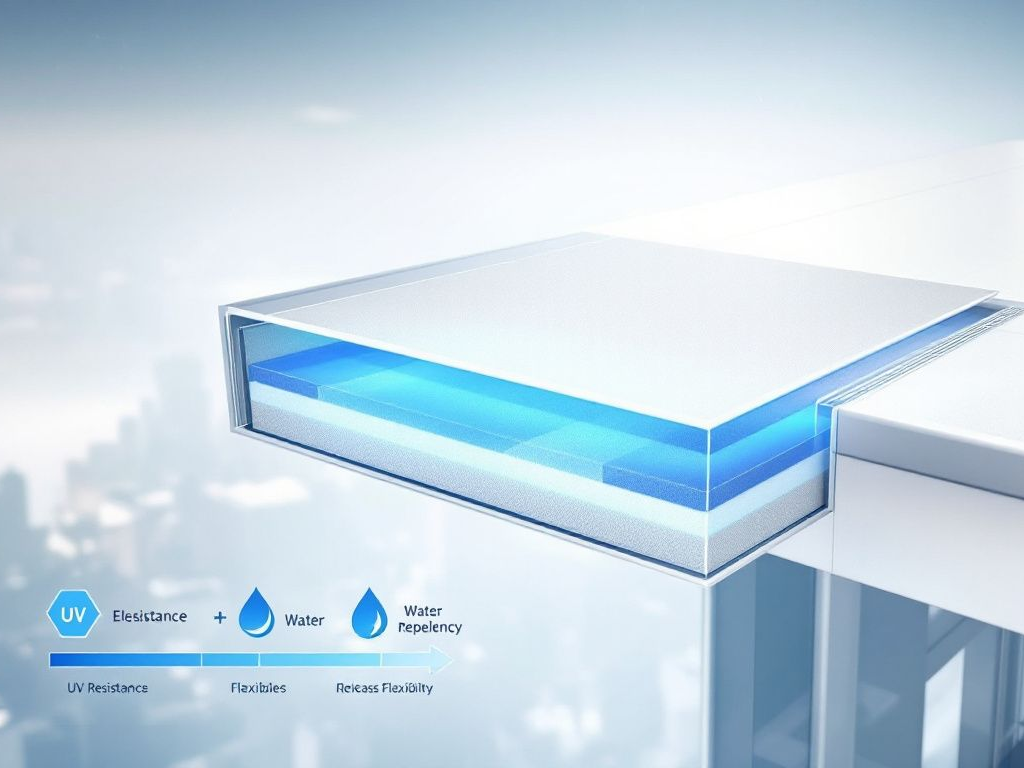

Elastomeric coatings are designed as a fluid-applied, flexible membrane that serves to safeguard and prolong the life span of an existing roof. Possessing extraordinary stretchability with elongation capabilities ranging between 300% to 800%, these elastomeric coatings can expand and retract in unison with movements on the roof surface. The elastic properties are essential for conforming to the changing dynamics of a roofing system, ensuring consistent protection over time.

Upon application, these elastomeric roof coatings create a continuous waterproof barrier that defends against external elements. This seamless coating not only bolsters durability but also offers a cost-efficient solution compared to completely replacing the entire rooftop. By installing an elastomeric coating on your property’s roofing system, you’re upholding both its structural integrity and visual appeal by creating a robust layer of protection.

Commercial

ButtonTypes of Elastomeric Roof Coatings

Various forms of elastomeric roof coatings are available to cater to diverse roofing requirements, including acrylic, silicone, and polyurethane options. These types of coatings provide roofs with a resilient shield that greatly prolongs their lifespan by defending against the elements.

Understanding the distinctive qualities inherent in each coating type is crucial for choosing the most appropriate solution tailored to individual roofing needs.

Acrylic Elastomeric Roof Coatings

Elastomeric roof coatings, specifically acrylic ones, are water-based substances best suited for angled roofs. They function as a paint-like liquid that repels both heat and UV rays to safeguard the roof against environmental damage while also prolonging its service life. The high reflective property of these coatings significantly contributes to lowering energy costs by reflecting sunlight away from the building.

These acrylic elastomeric coatings stand out for their cost efficiency in terms of protecting various roofing materials like concrete or modified bitumen. They not only ensure robust protection but also help reduce cooling expenses, which makes them an advantageous option for residential and commercial structures alike. These coatings offer steadfast performance with enduring advantages when applied correctly on roofs.

Silicone Roof Coatings

Renowned for their resilience to ponding water, silicone roof coatings are especially beneficial for flat roofs. These robust coatings serve as a waterproof shield that guards the roof surface against water seepage and ensuing damage. Their formidable durability helps keep the roof protected even in harsh weather conditions.

These elastomeric coatings boast superior UV resistance, reflecting much of the damaging rays while minimizing heat uptake. This reflection not only prolongs the life of the roof, but also aids in keeping energy bills at bay by ensuring a cooler roofing system overall. For anyone aiming to upgrade both their roof’s endurance and its thermal efficiency, silicone coatings stand out as an optimal solution.

Polyurethane Foam Coatings

Elastomeric coatings crafted from polyurethane foam are renowned for their superior impact resistance and enduring quality, making them an excellent choice under a wide range of environmental conditions. By creating a monolithic layer across the roof, they act as an effective thermal barrier that mitigates temperature fluctuations. This characteristic is especially valuable in regions experiencing severe weather changes, ensuring consistent protection for the roof throughout the year.

Polyurethane foam coatings not only offer high resistance to impacts, but also serve to effectively seal off diminutive cracks and apertures, thwarting water ingress and bolstering the overall structural soundness of the roof. For building owners who prioritize a robust and long-lived roofing solution capable of resisting rigorous environmental challenges over time, this type of coating presents an ideal option.

Benefits of Elastomeric Roof Coatings

Property owners find elastomeric roof coatings appealing due to the myriad of advantages they provide. These benefits include decreased energy costs and an increase in roof longevity, leading to substantial savings.

Elastomeric coatings act as a robust defensive layer over the roof, safeguarding it against extreme weather and detrimental environmental elements, which ultimately contributes to extending its service life.

Commercial

ButtonEnergy Cost Reduction

Elastomeric coatings on roofs serve as a powerful tool for diminishing energy expenditures. These coatings, known for their high reflectivity, are capable of bouncing back around 90% of solar energy away from the building. This reflection considerably decreases cooling requirements by maintaining much cooler roof surfaces than those without coatings, thereby offering substantial savings on energy bills.

Roofs treated with elastomeric substances manage to stay noticeably cooler even under intense heat conditions compared to traditional roofing materials. Notably, silicone-based elastomeric roof coatings provide robust UV ray protection and can deflect an impressive 80-90% of these potentially damaging rays. Such capability plays a pivotal role in lessening cooling demands while boosting overall energy efficiency within the building envelope.

Extended Roof Lifespan

Elastomeric coatings can extend the life of a roof by 10 to 25 years, offering an economical option for upkeep. These coatings create a protective shield on roofs that guards against the detrimental effects of weather conditions and UV rays, thus greatly improving their durability and extending their lifespan.

For these elastomeric roof coverings to maintain their effectiveness, it’s crucial they be applied correctly and undergo routine evaluations every 15-20 years. Doing so ensures any damage from elements such as wind, rain, or debris is promptly addressed keeping the roof in prime condition over extended periods.

Environmental Benefits

Elastomeric coatings for roofs contribute to environmental preservation by reducing waste and promoting energy conservation. These contemporary elastomeric roof coatings are often produced with a low content of volatile organic compounds (VOCs), positioning them as an eco-friendly roofing option that is in harmony with sustainable building practices and aids in fostering a cleaner ecosystem.

These roof coatings assist in diminishing the use of energy through their ability to reflect sunlight back into the atmosphere and dissipate accumulated heat, thereby curbing the need for air conditioning within buildings. By selecting elastomeric roof coverings, property owners can make a significant positive impact on the environment while simultaneously enjoying various advantages.

How Elastomeric Roof Coatings Work

By creating a pliable and substantial membrane that bonds with the roof surface, elastomeric coatings serve to shield roofs. To attain the desired level of thickness for enduring protection against environmental factors like UV radiation, it is often suggested to administer two layers of these coatings. Elastomeric roof coatings have an approximate tenfold greater thickness compared to standard paint and can be applied in a similar fashion, offering strong defense.

Prioritizing comprehensive cleansing and mending any fissures or perforations on the roof’s surface is crucial for ensuring proper adhesion and functionality of elastomeric roof coatings. Once set in place, these robust coatings generate an impervious barrier that patches up small crevices and punctures, averting moisture penetration while bolstering the structural soundness of the entire roofing system.

Commercial

ButtonFactors to Consider When Choosing an Elastomeric Roof Coating

Choosing the right elastomeric roof coating involves considering factors like climate conditions, roof material, and specific performance needs. Evaluating properties such as elongation, permeability, tensile strength, reflectivity, solids by volume, and emissivity is essential for an informed decision.

Durability and Impact Resistance

When selecting an elastomeric coating for a roof, it’s essential to consider both durability and the ability to withstand impacts. Coatings made of polyurethane foam stand out due to their exceptional toughness and capacity to endure harsh weather conditions. They offer formidable defense against damages from environmental elements such as hail or intense rainfall.

Opting for a sturdy elastomeric coat like one made with polyurethane can guarantee extended performance and shield against various environmental hazards. Such resilience is crucial in enhancing the lifespan and dependability of roofing systems, thereby providing assurance to property owners intent on protecting their assets.

Reflectivity and Emissivity

Elastomeric roof coatings are known for their ability to reflect UV rays, effectively minimizing the absorption of heat by building structures. This key physical property enhances the energy-saving potential of elastomeric coatings as it can substantially reduce cooling costs and help control indoor temperatures more consistently during peak heat periods. Consequently, this leads to a decrease in energy expenses.

The application of highly reflective elastomeric roof coatings is beneficial because these surfaces reject a considerable amount of solar radiation that would typically be absorbed by roofing materials. By doing so, they contribute to maintaining cooler interior spaces within buildings throughout times when external temperatures soar. Selecting such coatings proves advantageous for any building proprietor seeking efficiency in managing energy consumption and related costs.

Application and Maintenance

Elastomeric roof coatings require a specific application method, starting with a base coat primer and followed by the addition of two finishing coats. This approach secures the required thickness for superior performance while facilitating future upkeep through an easily renewable protective coating, thereby reducing repair needs over time. To maintain roofs in prime condition and prevent issues, it is advised to conduct inspections twice annually. Such practices prolong the serviceable life of elastomeric roof coating systems.

To maximize their lifespan, elastomeric roof coatings must be meticulously maintained with attention paid to achieving at least 20 mils in dry film thickness—this assures both efficacy and durability of the coating. By adopting this diligent care strategy early on, one can safeguard their investment while preserving peak functionality within their roofing system’s operation

Cost of Elastomeric Roof Coatings

The cost of elastomeric roof coatings can vary based on several factors, including the type of coating, roof material, and necessary preparation. On average, the national cost for roof coating is approximately $1,250, with a typical range from $500 to $2,000.

Acrylic elastomeric coatings generally cost between $0.15 and $0.80 per square foot for materials, while installation costs range from $0.50 to $3.00 per square foot. Silicone roof coatings cost between $0.50 and $1.40 per square foot for materials. Total installation costs fall within the range of $1.50 to $4.50 per square foot. Polyurethane roof coatings range from $0.45 to $1.30 per square foot for materials, with installation costs between $1.50 and $4.00 per square foot.

Despite the initial investment, elastomeric roof coatings are a cost-effective solution compared to a full roof replacement, offering long-term savings and benefits.

Lancaster Roofing & Construction

Common Issues Addressed By Elastomeric Roof Coatings

Elastomeric coatings for roofs present a strategic measure to combat various roofing challenges, providing substantial benefits for property owners. The uniform application of these roof coatings bridges gaps and crevices, significantly diminishing the probability of water ingress. By establishing this impermeable membrane over flat roofs, they not only enhance longevity but also ward off expensive maintenance issues.

Such elastomeric roof applications serve as a bulwark against standing water by discouraging pooling on level surfaces. They offer additional defense from severe climatic conditions and the deteriorating effects of UV rays, thereby bolstering their robustness and extending their service life. These coatings are particularly adept at adjusting to changes in temperature that cause expansion and contraction in roofing materials—actions which could otherwise lead to cracking—and thus preserve the cohesive integrity and operational status of the roof structure.

Why Choose Lancaster Roofing for Your Elastomeric Roof Coating Needs?

Lancaster Roofing stands as a premier commercial roofing contractor within Flower Mound and the greater Northern Dallas-Fort Worth vicinity, celebrated for their proficiency in elastomeric coatings. Their skilled application of top-tier elastomeric coatings enhances both the longevity and functionality of roofs, establishing them as a trusted provider for various roofing services across the area.

They offer an extensive array of services encompassing consultations, application processes, and ongoing maintenance related to elastomeric roof coatings. Their offerings include options like Acrylic Roof Coatings and Silicone Roof Coatings designed to cater specifically to your individual roofing system’s requirements.

To acquire Details or receive a free estimate from Lancaster Roofing, reach out by dialing

(214) 247-6388.

Summary

Elastomeric roof coatings deliver a range of advantages, such as enhanced longevity of your roof, diminished energy expenditures, and support for environmental preservation. These coatings come in various types including acrylic, silicone, and polyurethane. Each is designed to cater to distinct roofing requirements by offering a resilient layer that guards against the elements while improving the strength of your roof.

Selecting an appropriate elastomeric coating requires consideration of aspects like long-term durability, ability to reflect sunlight and upkeep necessities. With Lancaster Roofing’s depth of knowledge and extensive service offerings, they are perfectly positioned to assist with all your roofing needs. Take advantage of the many benefits provided by elastomeric roof coatings to guarantee both improved performance and extended life span for your roof.

Frequently Asked Questions

What are elastomeric roof coatings?

Elastomeric roof coatings are flexible, fluid-applied membranes that create a waterproof barrier, protecting and extending the life of existing roofs while adapting to their movements.

How do elastomeric roof coatings reduce energy costs?

Elastomeric roof coatings effectively reduce energy costs by reflecting up to 90% of the sun’s energy, which lowers roof temperatures and minimizes cooling expenses.

This results in a more energy-efficient building.

What types of elastomeric roof coatings are available?

Elastomeric roof coatings come in three primary varieties: acrylic, silicone, and polyurethane. Each type provides unique benefits to cater to different roofing requirements.

Choosing the right elastomeric roof coating can significantly improve your roof’s longevity and overall performance.

Why should I choose Lancaster Roofing for elastomeric roof coatings?

Opting for Lancaster Roofing to apply elastomeric roof coatings guarantees expertise in boosting the durability and performance of your roof.

With a full range of services that span from initial consultation to ongoing maintenance, they are a reliable selection for those in the Northern Dallas-Fort Worth region.

How often should elastomeric roof coatings be inspected?

Elastomeric roof coatings should be inspected twice a year, ideally in the spring and fall, to maintain their condition and address any potential issues promptly.

Regular inspections help prolong the life of the roof.